Test Solution for Remote Control Module Production Line

In 1955, Eugene Polley created the first wireless TV remote controller. Since then, the application of the "remote control" device has undergone many stages (from the infrared remote control to the Internet of Things – IoT – control). It has a wide application, from multiple household appliances to application in the military, in daily life, in industrial production, and in other fields. The control media is also changing with technical development, from visible light to wireless signal with multiple modulation modes. With the wide application of wireless technologies, users impose high demands on products. Because of the increasing demand, completing the product test in a fast and cost-efficient way has become an urgent issue for various remote controller manufacturers. After exploring the test process of many manufacturers of remote control devices, e.g., remote control toys, remote control keys, remote control electric curtains, and intelligent lighting remote control, RIGOL's technical support personnel can provide a complete set of solutions for customers with RIGOL products.

The remote control device is composed of two modules: transmitter and receiver modules. The transmitter module is generally independent, whereas the receiver module and the actuator are bound together. Therefore, the test consists of two parts: remote controller test and receiver module test.

Remote Controller Test

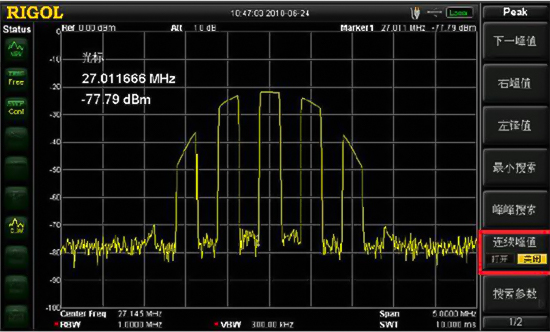

Currently, the main modulation modes adopted by the remote controller is ASK and FSK. The carrier frequency point for the remote control key is mainly 315 MHz and 433 MHz, and the one for the remote control toy is generally below 100 M (e.g. 27.145 MHz, 49.86 MHz, etc.). The currently popular intelligent lighting remote control generally uses the 2.4 GHz Bluetooth signal.

During the production test, test engineers mainly focus on the following elements:

- Technical requirements

Technical requirements for performing the remote controller test mainly include center frequency modulation, transmission power, spectrum diagram, function test, and test data storage. - Speed

To achieve a certain output and complete the production task, speed is seen as one of the most important elements in the test scheme. - Cost

Cost is a crucial element of an enterprise success at any time.

Among the technical requirements for the remote controller test, the center frequency and transmission power are core data; they are basically the test items for all kinds of remote controllers. The spectrum diagram and function test are not mandatory, so you can select either of them as a test item in the production. The storage and backup of the test data is usually required by OEM enterprises and enterprises having higher quality requirements.

Increasing the test speed while ensuring the product quality is a common demand for all enterprises. In this article, we introduce two ways of speeding up the test and improving the production efficiency.

Improving the test speed and easy-to-use tool features

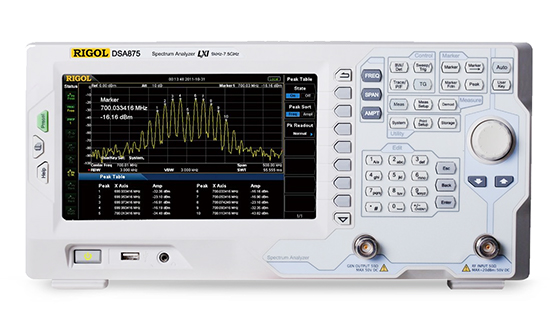

Users hope that the tool can generate the spectral line and frequency/amplitude data immediately after the tools has tested the product, but this process often takes a long time. RIGOL DSA Series Spectrum Analyzer is fast responsive, and its "Cont Peak" (continuous peak) function can guarantee the real-time capture of the current modulation carrier frequency and transmission power while capturing the signal's spectral line. The test speed is up to 5s for each product (including the worker's operation time).

Customizing the test system and accomplishing the auto test

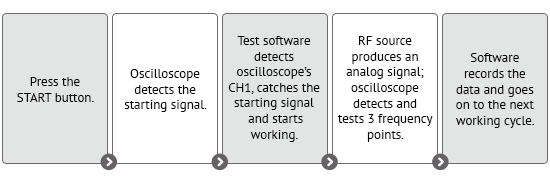

To further speed up the test, save test data in a timely manner, and unify the product testing standards, RIGOL engineers have developed a remote controller auto test software for their clients.

Test workers only need to press the remote control button, and the whole test process and analysis will be performed by the software. They just need to check whether the result display button on the computer is green. When the software is used, the test speed can be up to 2s for each product.

In terms of cost, RIGOL DSA800 Series Spectrum Analyzer is highly cost-efficient, also offering superb performance and stability in the industry. It adopts the digital technology, and its bandwidth ranges from 9 KHz to 7.5 GHz. Compared to similar products of other companies, its price is extremely competitive, thus offering an affordable instrument with an excellent performance.

Receiver Module Test

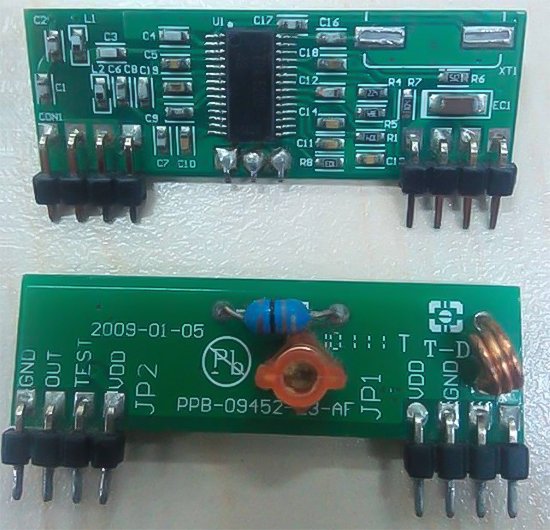

The receiver module is another component of the remote control device. It is a small circuit board usually connected with the actuator. For example, the receiver module of the remote control key of a car is connected with the controller board of the door and the window, as well as that of the trunk.

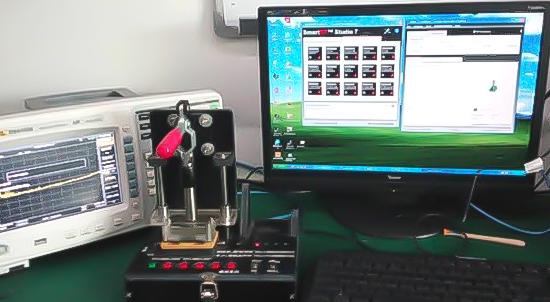

The test for the remote controller receiver module is a bit more complicated. The test principle is roughly as follows: after the module receives a lower level signal--generally a control signal with a nominal sensitivity, it can still fully demodulate the information contained in the control signal. This process requires two instruments: a signal source and an oscilloscope.

Signal source: simulates the control signal. It needs to simulate various modulation signals and can output the lower level signal. Since different manufacturers have different ways of signal modulation encoding, it is preferable to use the signal source supporting custom modulation pulse sequence during the test.

Oscilloscope: tests the signal demodulated by the receiver module.

As there is a range for the nominal frequency band of the receiver module, it is advisable to test the following three frequency points: upper limit frequency, nominal frequency, and lower limit frequency. The efficiency will be very low if the frequency points are repeatedly set manually, so the test for the receiver module generally adopts the automatic test. For example, the test efficiency of the receiver module test system customized by RIGOL for many clients is 5s for each product. The test process is as follows: