Fiber Optic Precision Cleavers

A cleaver is a mechanical precision device whose task is to cleave the end of an optical fiber so that the cleavage surface was as flat as possible and if possible at 90° angle to the fiber itself. However, there are specialized cleavers and cleavers with electronics that allow making cleavage angles different from 90°.

The quality of a cleaver is determined by the following statistical parameters: how smooth the cleave is, how the angle of the cleavage surface is different from 90°, how often the cleaver breaks fibers, how convenient it is to work with it, what the cleaver’s capacity is, etc.

Why Do I Need a Cleaver?

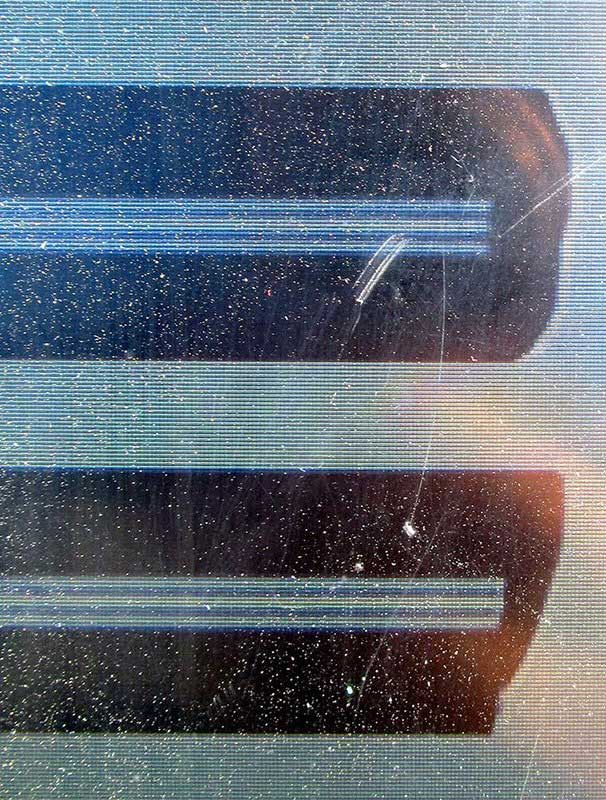

If we just break off the end of the fiber with tweezers, then the probability of having a proper cleave will be extremely small and fusion splicing will definitely not be good. A couple of examples of bad cleaves are listed below.

A poor cleave on the fusion splicer display (view of the same fiber with two cameras)

A poor cleave on the fusion splicer display (view of the same fiber with two cameras)

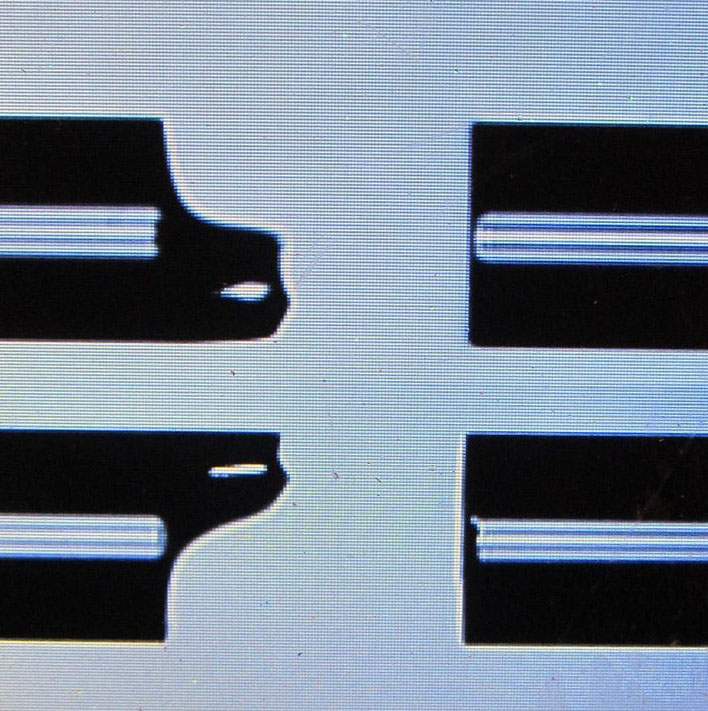

Left fiber with a poor cleave, right fiber is normal (a small black defect on the right fiber is frequent occurrence; it doesn’t usually affect splice, since it is located on the edge of the fiber)

Left fiber with a poor cleave, right fiber is normal (a small black defect on the right fiber is frequent occurrence; it doesn’t usually affect splice, since it is located on the edge of the fiber)

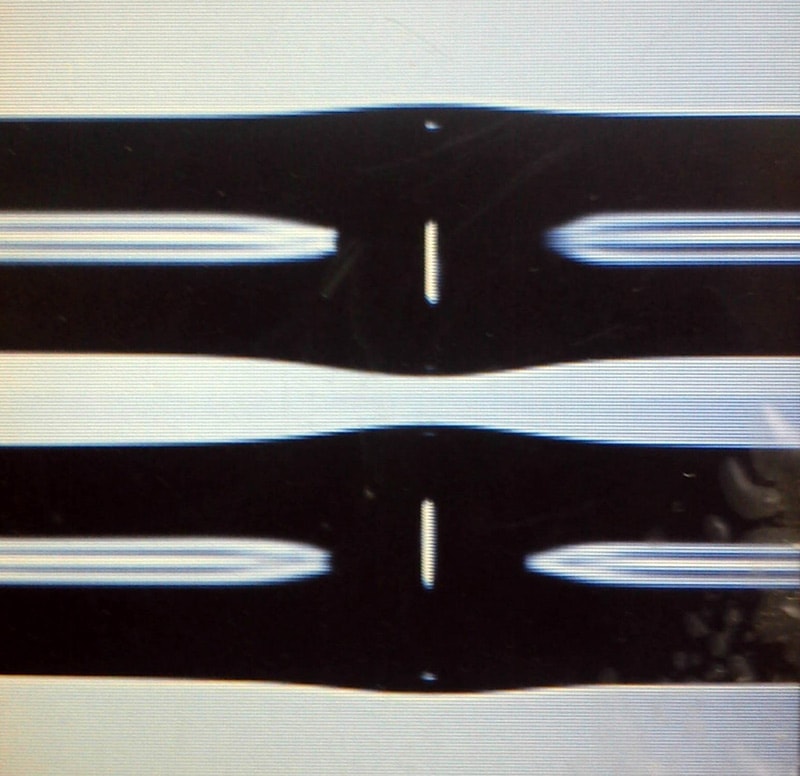

The splice itself will look like this (if you still “force” the fusion splicer to fuse – despite its "protests").

A poor cleave on the fusion splicer display (view of the same fiber with two cameras)

A poor cleave on the fusion splicer display (view of the same fiber with two cameras)

A typical "bubble". Splice needs to be fused again. A line with this splice will not work. In a best-case scenario, the line will work – with a bunch of packet loss - if it is short, but the attenuation here will be a few decibels.

Therefore, you will need a special tool to gently prepare fibers for splicing.

Choosing an Optical Fiber Cleaver

Precision cleavers, as well as fusion splicers, differ. They can be more expensive, less expensive, much less expensive, or they can be even limited purpose devices. If you can compromise on the point of a fusion splicer and save 200–250 USD when buying a good Chinese device instead of a Japanese one, it's better, however, not to do it with a cleaver. Yes, you are right: in addition to buying a Chinese set of a fusion splicer with a Chinese precision cleaver in the package, I advise you to additionally buy a good Japanese cleaver, and use the Chinese cleaver as a backup (or as an additional tool – to speed up the work). A good cleave is already 50% of successful splice, while speed and convenience in operation is the best guarantee that the operator will be able to fuse more fibers in a day.

Fujikura CT-30

Fujikura CT-30

INNO Dragon

INNO Dragon

Fiber Optic Cleaver Operation Algorithm

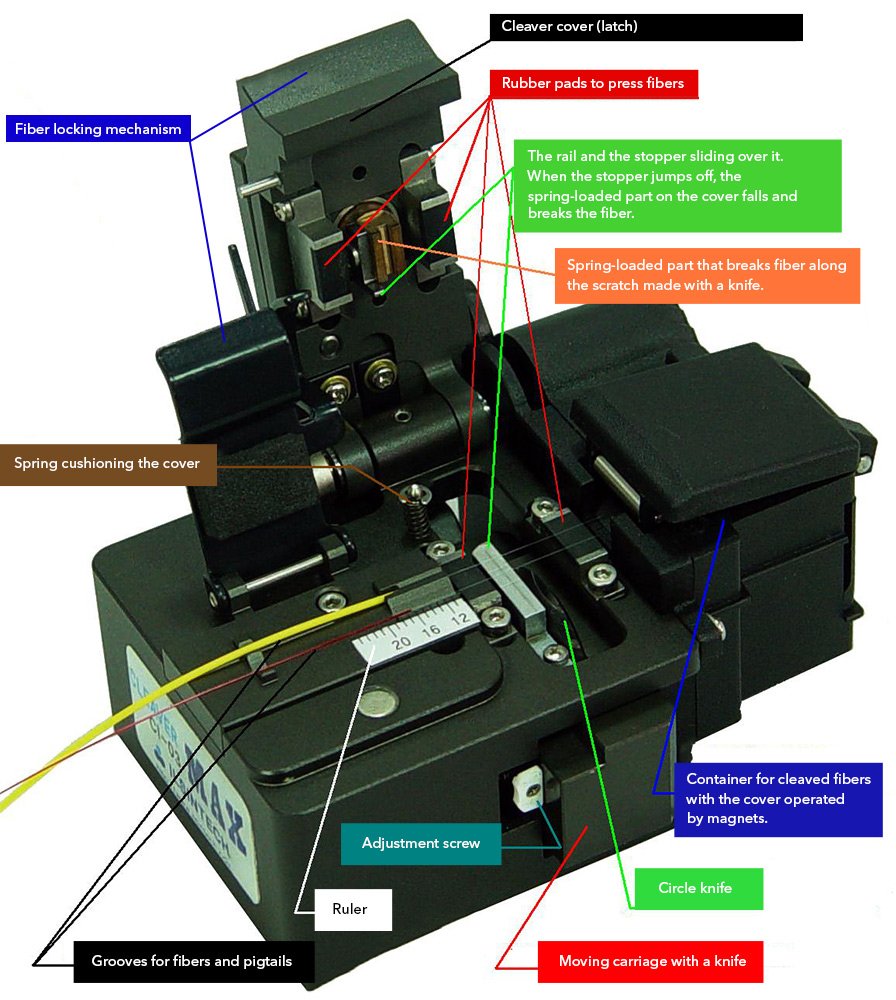

Let us describe the algorithm of the cleaver operation using Fujikura CT-30 / Fujikura CT-30A as an example.

Quite a lot of operators have this model. It is a really good, thoughtful and convenient device. The instrument is compact and reliable, you can cleave with it using minimum movements, and there won’t be any unpleasant surprises. Remember that you need to use a cleaver having a collector for cleaved fibers. There are other models of Fujikura cleavers, which are positioned as a more modern, compact and inexpensive replacement for CT-30A, but never as a higher-quality replacement. Still CT-30A is a classic.

Using Fujikura CT-30A

When using CT-30A, you will need to:

- Lift the carriage with a blade.

- Lay the fiber.

- Close the fiber locking mechanism.

- Press the cover – latch – making a cleave.

- Open the locking mechanism.

- Take out the cleaved fiber.

With some cleavers, even less action is needed: you don’t even need to lift the carriage, because it is lifted when the cover (latch) opens and produces a working pass when it is closed.

Using Jilong KL-280

If we talk about the sequence of actions in a simpler and less expensive cleaver using the example of Jilong KL-280, then you need to conduct more operations for the cleave.

- Lift the carriage with a blade.

- Lay the fiber.

- Close the fiber locking mechanism.

- Close the cover (latch).

- Manually pull the carriage with a blade – making a cleave.

- Open the cover (latch) overcoming magnet power (not convenient to do it using one hand).

- Open the locking mechanism.

- Take out the cleaved fiber.

It would seem that there are only two additional actions. However, it affects ergonomics, time, the amount of work done, which will be bigger if all operations are performed quickly.

Next, this precision cleaver sometimes breaks fibers, and cleaning or scavenging does not help much. You can cleave fibers OK for twenty times; then the 21st time is when you take out the fiber and it is broken by the cleaver in one of its "favorite" places: before or after the rubber pad, or between the pad and the blade. You need to strip it again and wipe with alcohol.

The capacity of a 16-position circular knife by the Chinese precision cleaver is quite small: you need to turn to the next position quite often (in comparison with Fujikura), otherwise it will start cleaving poorly. When the knife has done a full turn, its corresponding adjusting screw is lifted some microns and it does the second full turn again. After that, the second lift and the third turn, and then the knife should be replaced.

The full capacity of a good Japanese precision cleaver is around 48.000 cleaves.

Circular knives for all sorts of cleavers

Circular knives for all sorts of cleavers

There are other cleavers. For example, a cheap pin-shaped “sorry excuse of” a cleaver that does not show accurate perpendicularity of the cleavage and which I would not advise to use at all.

Optical Fiber Cleaver Operation

The principle of the cleaver operation is as follows:

- The fiber (stripped of varnish and wiped of dirt) should be well fixed.

- When cleaving, a cross micro-scratch is made on the fiber with a diamond knife or a knife made of hard steel.

- A force is applied to the fiber so that it cracked accurately on the scratched place.

Let us consider in more detail the cleavage of one fiber with a typical precision cleaver.

- The optical fiber is stripped to a certain length, it is well wiped with a lint-free alcohol cloth. Do not touch the glass with your fingers!

- Open the locking mechanism and the cover (latch) gently lay the fiber in the cleaver. It is important not to smear the fiber at this point and not to touch the knife with your fingers! Fibers with lacquer coating are inserted into a thin groove, and pigtails in yellow coating are inserted into the thick one. You cannot insert very thick patch cords; therefore, if you need to fuse a patch cord, it needs to be stripped like a cable, with the fiber released.

- The fiber should be inserted so that the boundary between the lacquer coating and glass lies on the desired gauge mark. This figure tells us how many millimeters of glass will stick out of the varnish after cleavage. For each fusion splicer this mark/figure is different (for example, for Jilong KL-280 it is 16 mm), you just have to remember it for your device. If you insert the fiber so that a shorter length will be cleaved, the fusion splicer will not have enough range of carriages to bring the fibers together, and it will give a bleep and display the error "Feed limit" or "Insert fiber again". If you cleave it off so that there is too much glass on the contrary, everything will be cleaved and fused OK, except that the protective sleeve (if it is of the "short" standard - 40 or 45 mm) can be shorter in length than the bare glass portion of the fiber, and won’t fully protect the stripped fiber. In this case, the fiber without protective coating/varnish will break very easily if bent at the exit from the protective sleeve (with the same laying), and this splice needs to be performed again.

- Make a cleave. In some models, you just need to press the cleaver cover (latch), in other cases you need to close it, push the carriage with your finger and open it again.

- Open the locking mechanism, open the cover (latch) if necessary and gently take out the cleaved fiber. You can understand whether it is broken immediately, even before you take it out. You cannot put it anywhere except as into a fusion splicer, because whenever it touches anything it will immediately become dirty. It should be inserted into a fusion splicer so that it does not touch the end against any parts and surfaces: if you accidentally touch the end of the cleaved fiber against ta V-groove or an electrode when inserting it into the fusion splicer, you will see a ton of dirt on this fiber when trying to bring fibers together.

Fibers are dirty; besides, a large particle of dust is stuck against the fiber

Fibers are dirty; besides, a large particle of dust is stuck against the fiber

In fact, you can try and clean this soiled fiber – at first you just wipe it with a napkin and then wipe the fiber end with the alcohol tissue – and then dry tissue. With 60% certainty, it will then be clean and will fuse successfully. However, it is better to immediately strip and cleave it again, or even better – not to drop or soil the wiped and cleaved fibers. - Depending on the cleaver design, the cleaved fiber end (1) is pulled into the fiber container; (2) remains sticking out in the "rollers" or, if there is no container, (3) falls on the table next to the cleaver. Accordingly, in the first case you just need to check whether the fiber has been properly pulled into a container (too long will not fit, so you don’t need to strip fibers from lacquer by 10 cm; sometimes, the fiber can somehow come off and not be pulled into a container). The second case requires rotating the rollers with a special wrench or handle so that the fiber is drawn between the rollers into the container. Finally, in the third case – you need to immediately attach a piece of adhesive tape to the fiber so that the fiber sticks to it, and then cover these fibers stuck to the tape from all sides. In general, using a cleaver without a fiber container is NOT recommended, and we’ll explain the reason for it below.

Working with Fiber Optic Cleaver: Safety Rules

Pieces of optical fiber, especially fiber without varnish, are a dangerous waste product. In countries with a better culture of waste processing, they are collected and disposed of. In our country, of course, it depends, but still this is not a reason for throwing fibers around after your work. All fiber fragments must be carefully collected! If such a piece of fiber, a barely noticeable, gets into food or into your drink, it can lead to problems like ulcer or the like problems. If it sticks into the body and breaks there, then in theory, this piece can reach your heart travelling via the blood-vascular system; however, it usually becomes a nasty – difficult –splinter no x-ray can find, which crumbles when you try to pull it out with tweezers. In addition, fibers in clothes, shoes or in car seats are not the most pleasant things to have. Thus, you should follow the rules below:

- No food in the workplace.

- All fibers to the last should be carefully collected. Even if you work in a cellar foundered by sewage, it is not a good reason to leave litter – fibers – about!

- Cleaver must have a container for cleaved fibers.

- You must use protection means: goggles, special work clothes and apron.

Back to our sheep or back to our cleavers.

You understand that a successful cleave depends on microns. Therefore, the cleaver should be protected from blows, falls, dirt and “all thumbs” operators as fervently as the fusion splicer. It is not accident that the device is packed in a soft-filled box.

You cannot screw tuning pegs, not being exactly sure what you are doing. You cannot fumble inside with your hands or solid objects – you can cut yourself and ruin the blade sharpening. You cannot leave the cleaver in a humid environment for a long time.

You just need to remember: a fusion splice, a cleaver and a reflectometer are three irreplaceable tools. Your work will stop if you don’t have any of them. Yes, you can actually cut or terminate the cable with an ordinary knife instead of the NIM-25 tool. Yes, you can remove the lacquer from the fiber with a razor instead of a stripper. However, making a proper cleave with impromptu means is unrealistic and fusing fibers with materials on hand is impossible.