Mechanical Fiber Optic Splicing

Page Content

- Optical Fiber Mechanical Splicing Advantages

- Optical Fiber Mechanical Splicing Disadvantages

- Optical Fiber Mechanical Splicing Standards

- Conclusions

Initially, mechanical optical fiber splicing used to be seen as a cheaper alternative to fusion splicing. As time went on, fusion splicing equipment was becoming less expensive and the requirements to fiber quality / line characteristics were increasing, so mechanical splicing has eventually lost its popularity.

Optical Fiber Mechanical Splicing Advantages

- You do not need to invest in a fusion splicer (please note that you will still need a cleaver and all other tools).

- The operator’s mobility is higher – you do not need to carry around a large case with a fusion splicer.

- Suitable as an inexpensive backup option for a temporary repair / link restoration, when you need connection immediately but there is no fusion splicer nearby or you are in the middle of the field with a flat battery.

- Typically, mechanical connectors can be installed into a standard cassette instead of a splice protection kit.

- A mechanical connector can usually withstand several fiber terminations, while the splice protection sleeve is disposable, i.e., can be used once only.

Optical Fiber Mechanical Splicing Disadvantages

- With mechanical FO splicing, connection losses are much higher than with fusion splicing.

- Time-wise, you will invest in mechanical FO splicing as much time as you do in fusion splicing.

- Reliability is lower. Sometimes connection may be broken (due to vibration, time), especially if you installed used Fibrlok / Corelink, and it will take a long time to find out which of these Fibrlok / Corelink splices have fallen off this time.

- A fusion splicer costs a lot, but later the cost per one splice is very low. With mechanical connectors, it is the exact opposite.

- For many customers, mechanical jointing is unserious.

It can happen that a short line is installed successfully and works well almost without any packet loss with 3-4 mechanical connections/joints, which were made even without using a cleaver! However, that’s possible only thanks to immersion gel and dumb luck (cleaves are more or less even and don’t resemble a tip of the spear). In fact, such a situation is still from the science fiction domain and for mechanical splicing you still need a regular cleaver. Then you can get signal loss in mechanical joints from about 0.1 dB and higher: it is a lot for a backbone, but as a temporary option or for a short secondary line – it will pass.

Optical Fiber Mechanical Splicing Standards

There exist many standards of mechanical splicing.

Probably the most well known standard of mechanical connection is Fibrlok.

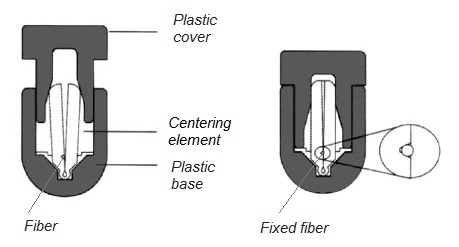

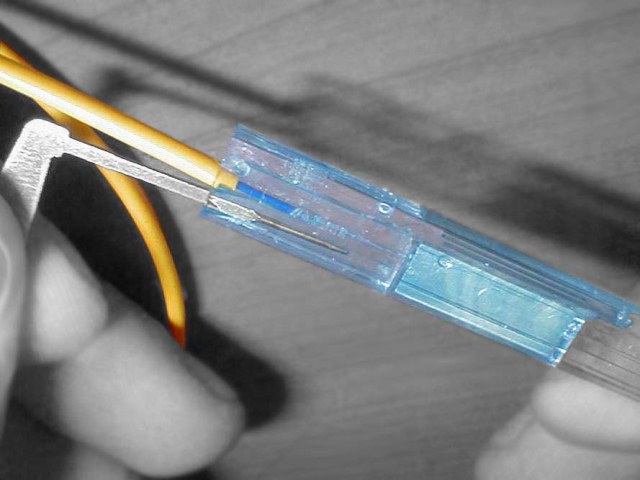

The connector is a plastic block consisting of three parts. The first part is a plastic, U-shaped groove base. Two other parts are inserted into this block: a plastic inverted-U-shaped lid with latches and a metal V-shaped groove with a round recess – ‘bed’ – for fibers at the bottom.

Prepared cleaved fibers are inserted on both sides into this V-shaped groove. Usually their ends are dipped in special immersion gel to reduce losses and reflections caused by light transition from glass into the air and back into glass. There already may be a droplet of immersion gel inside the Fibrlok. The refractive index of this gel is close to the refractive index of the fiberglass in the cores. The gel often has hydrophobic properties.

The groove itself can be slightly bent around the laid fibers, vaguely resembling piano hinges. When fibers are laid, an inverted-U-shaped clamp is put on top of this groove, which, when dressed, compresses the V-groove, tightly fixing the inserted fibers, and is fastened by latches.

There are other standards, for example, Corelink splice. The principle of operation is similar to Fibrlok splice, and it is opened with a key.

Conclusions

To conclude, there are several standards of mechanical fiber optic connectors. You can carry around a dozen of Fibrlok splices just in case, but it is highly questionable whether it's reasonable to use them on a permanent basis. A optical fiber splicing machine, of course, is rather expensive, but after a couple of large projects, it will definitely pay. Please remember: when using mechanical splice you will need to buy mechanical connectors every time, which is costly; it takes as much time to assemble them as fusion splice takes; mechanical splice results in more loss and reflection; and reliability is lower.