Mechanical Splicing and Optical Fiber Fusion Splicing, Measuring and Aligning Fibers

Page Content

- Fiber Optic Arc Fusion Splicer

- Fiber Optic Fusion Splicer Classification

- Choosing a Fiber Optic Fusion Splicer

- Taking Care of a Fiber Optic Fusion Splicer

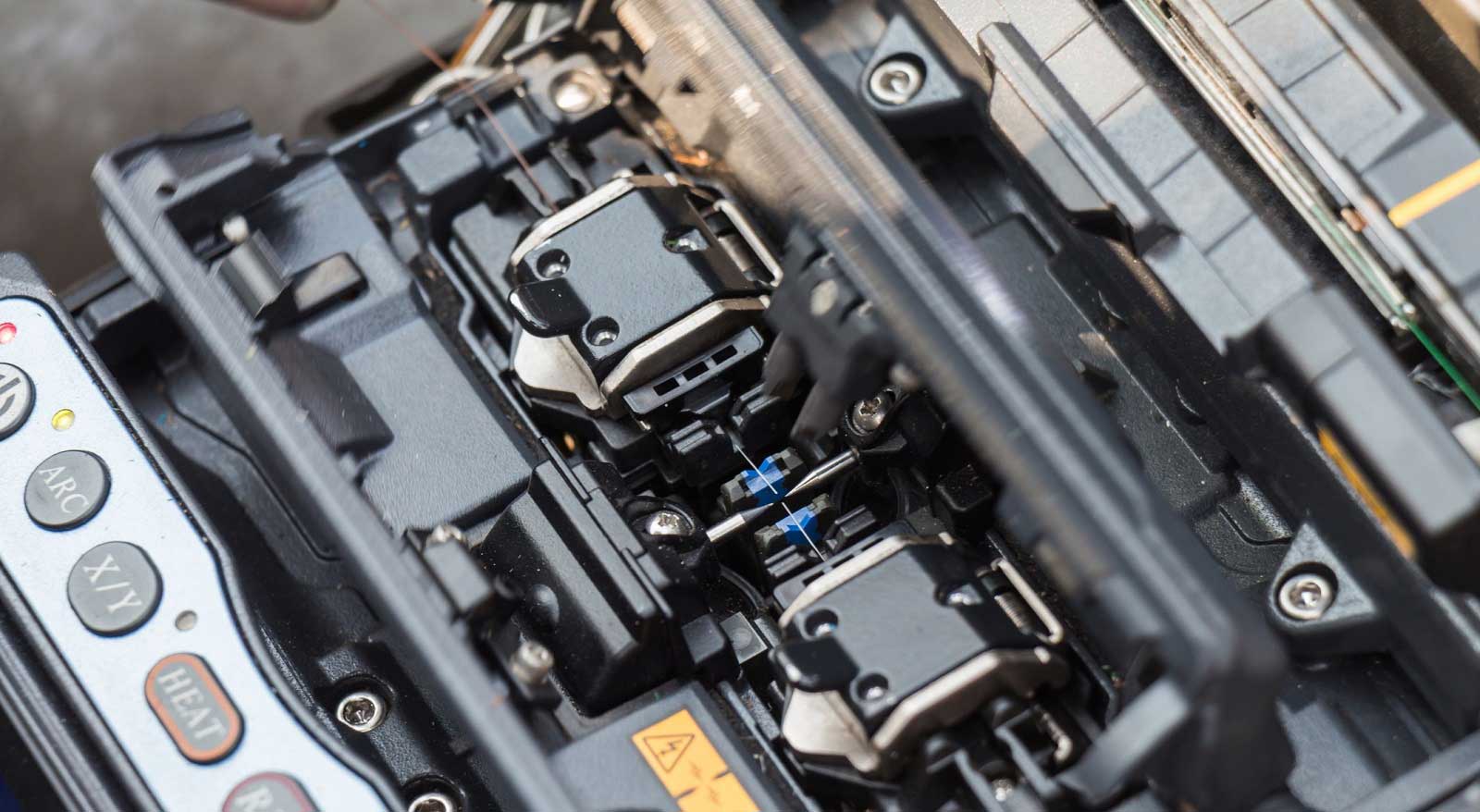

Fujikura 80S Fusion Splicer with open lid and fibers inserted

Fujikura 80S Fusion Splicer with open lid and fibers inserted

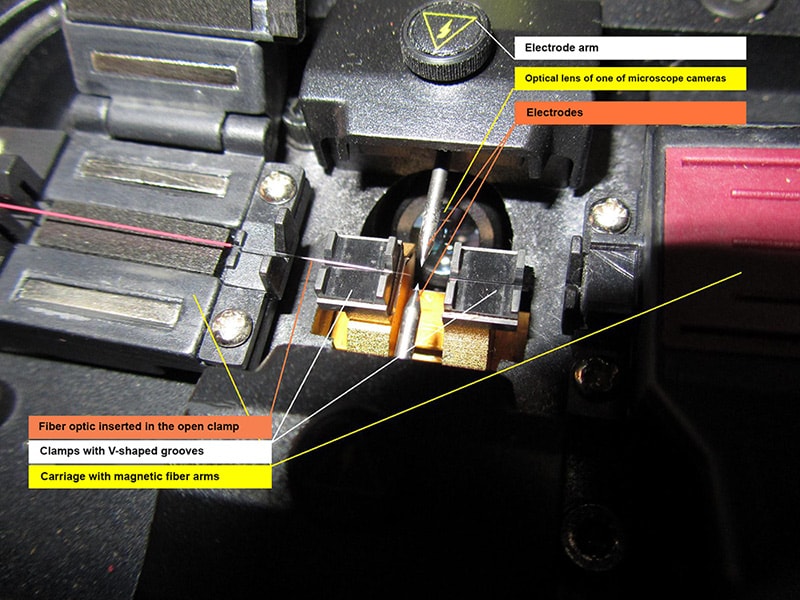

Looking under the splicer lid

Looking under the splicer lid

Fiber Optic Arc Fusion Splicer

Arc fusion splicer is one of the most costly and complex (along with the optical time domain reflectometer) fiber optic installation tools. This is a smart device, which performs the entire process of fiber alignment and splicing, and the operator only needs to prepare fibers, insert them into the device, and then to take them out, place the protection sleeve on the fiber and put it into the oven. In short, the operating principle of any fusion splicer is as follows:

- After the technician has stripped and cleaved the fibers, they are inserted into the device with the protection sleeve on and are fixed with clamps.

- The device starts moving the fibers – by itself or after pressing the button – bringing them together until they are seen by the CCD camera – an optical system consisting of microscope cameras and mirrors located on the inner side of the lid.

- When both fibers are in camera vision, the apparatus generates a weak electric arc of short length, which clears away microdust from fibers, which is usually still there no matter how careful the wiping was. It’s believed that this short electric arc also “fuses” fibers a bit preparing them for fusion splicing. If the fibers have non-combustible dirt on them, e.g., hydrophobic gel or finger oil, then this arc will only “bake” this dirt, and no kind of wiping will help – you will need to do the cleaving again. If the fibers are clean and cleaving was performed well, the device starts bringing them together in three axis using precise motors – first approximately (roughly), and then precisely. If the fibers are not OK – the apparatus informs you about it (by a notification on the display and a bleep sound) and refuses to continue fusion.

- When fibers are brought together and moved almost side by side, a base power arc is generated for a second or two. The fibers are heated, and when heated they are brought together more closely for fusion. After the arc is off, the splice point is cooled in a fraction of second.

- Based on the image, the device estimates whether there is any screw-up (good fusion splicing is practically unnoticeable), and attempts to define the attenuation at the splice obtained with inside light inspection. Information about the splicing (date, time, attenuation) is saved in memory, and nonresettable counter increases by one.

- The device tries to pull apart spliced fibers with dosed effort; if the splice does not break, then mechanical strength test – the proof test – has been passed successfully. Many people disable this test as unnecessary, since the word has it that the test can cause some damage to the splice when it is not yet cool enough.

- The jointer takes away the spliced fiber with care, places the protection sleeve on and puts the fiber in the oven where it is heat shrunk protecting the splicing joint from exposure.

- When the oven timer stopped, fiber with heated protection sleeve is taken out and the protection sleeve is put on a special shelf to cool down. If you put it into the stand on the cassette when it is still hot, the plastic will stick.

Fiber Optic Fusion Splicer Classification

Fusion splicers can be roughly grouped according to their purpose and functionality.

1) When good splice of single mode fibers is required

Such devices perform fiber alignment in V-groove both by cladding and by core, using the splice image from two microscope cameras (PAS – Profile Alignment System) located at 90° angle. This method is preferable to alignment by cladding only – the fact is that the fiber can have eccentricity, be slightly oval or have some axial displacement of the central 9-micrometer core. Servomotors in such devices can usually move the fibers towards each other and from each other, up and down, forward and backward; besides, microscopes on cameras can change their focus (for finer focus). Today, most operators cannot rotate the fiber along the longitudinal axis or tilt it to some angle to compensate for abnormality or deviation of the cleave angle from the norm.

These are expensive and high-quality devices, which are probably most often used (due to their flexibility and quality). They can perform approximate estimation of attenuation value while fusing; they calculate it using the splice image and a smart algorithm. Many models can intentionally fuse fibers with a shift when it is necessary to obtain an attenuator, so that the splice is with the set transmission loss. Some examples are the whole line of Japanese Fujikura from FSM-30S to 80S/70S, Sumitomo Type 39 (and others), Furukawa Fitel S178A; also, with great reserve – Chinese Jilong KL-260C, KL-280, KL-300/300T and some other Chinese models.

2) A cheaper option for fusing less critical and short lines, where the attenuation in splicing is not so essential

An operator brings together the fibers not by the core, looking at the camera image, but simply by moving along two very even V-shaped grooves, that is, there are no many servomotors involved. The camera and display are only for operator control and the loss estimate. It is assumed that the user will often fuse a multi-mode fiber. It is clear that the accuracy of bringing the fibers together and the splice quality will be statistically worse, since the smallest dust, imperfection and misalignment of optical fibers themselves or a micro scratch on the groove will sharply worsen the fiber core alignment and, accordingly, the quality of splicing. The price is lower than that of "professional" Japanese products, but higher than or comparable to "professional" Chinese. Fujikura FSM-18S, Fujikura FSM-17S and Sumitomo Type 46 serve as examples.

Fujikura FSM-18S

Fujikura FSM-18S

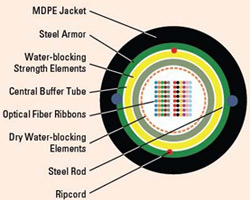

3) Ribbon fiber fusion splicers

The cable of this type is rectangular in section inside, and has ribbons made of several (usually up to 12) fibers.

A ribbon fiber fusion splicer normally fuses the whole ribbon; it is very time saving in this respect.

Fujikura FSM-60R

Fujikura FSM-60R

Sumitomo Type 66

Sumitomo Type 66

4) Special and laboratory fusion splicers

They are used for splicing special fibers, for example, polarization maintaining fibers (Fujikura FSM-100M, FSM-100P, FSM-45F). Such devices are very expensive; they have a bunch of flexible settings and require special cleavers. For example, you can make a precision cleave at an angle of 45 ° and fuse the fiber this way.

Fujikura FSM-100P

Fujikura FSM-100P

Each device has its own features and its own strengths. These can be high quality, high speed of splicing or speedy protection sleeve heat shrink. These can be having two ovens for protection sleeves, or possessing additional convenient features, or maybe a touch screen, or duplicated control buttons for comfort when working together, or super-increase in splice size, or being super compact, or shock-, frost- and wind-resistance, or just a bargain price. For example, Fujikura 80S is a recognized leader showing excellent quality, user-friendliness and speed, is resistant to moisture, dust and is shockproof, it is relatively compact, you can fine-tune its operation as needed, but the price hardly suits to your pocket, spare parts and maintenance are expensive. Chinese DVP-740, for example, is slower, less reliable, but the price is three times (!) less than the Fujikura. Jilong KL-300T is, according to many, the best option: it is essentially the redesigned Fujikura FSM-50S clone, which is much cheaper than Fujikura and Sumitomo, has good reliability, and fuses almost as well as Fujikura flagships. Next, what if you need a compact size? Then your choice is Furukawa Fitel, or something simpler – Fujikura FSM-12S. In short, for each task there is an option that is most suitable.

Choosing a Fiber Optic Fusion Splicer

Why, with such diversity, many people, despite the price, are striving to buy an expensive fusion splicer, preferably a flagship Japanese model, which is intended for fusing backbones?

The main point is multifunctionality and universal use (who knows what you will need to fuse tomorrow – a backbone, FTTx or PON?). You can also encounter lack of understanding with the client’s staff responsible for the object acceptance. From the technical point of view, it is quite clear that splice attenuation is not particularly critical for an FTTB network with its small distances or for 10 km long short lines; however, for 100-km-long backbones the splice loss of 0.15 dB is inadmissible. However, those who accept objects, especially major customers, will rarely listen to reason. They will most often require that any line (not just optic fiber, but the entire finished line – from cross case to cross case) fits into the values of attenuation not higher than 0.22 dB/km with the wavelengths of 1550 nm and 0.36 dB/km at 1310 nm. They are tough on it. On the one hand, their view is understandable; after all, one day – theoretically – you can also lay a critical backbone via this short line. On the other hand, however, at times their requirements are too rigid. It is clear enough that it is next to impossible to meet these requirements to the line using inexpensive fusion splicers. With high-priced equipment, you simply fuse all closures, and maybe then, after analyzing the measurements, you go through closures and fix a couple of minor screw-ups. With a low quality device, you need to deal with transmission losses repeatedly and for a very long time.

Taking Care of a Fiber Optic Fusion Splicer

You should take good care of fusion splicers. I think it's obvious, if you keep in mind their price. If you buy a device, and other people will operate it – then you need to implant this in your future workers. It is necessary to cherish the fusion splicer as an apple of your eye! Think over every step carefully. Is the device set safely? Is the desk safe? Will there be anything on top of it? Will the gust of the wind bring some dust from the road to the workplace? Is there going to be a rainstorm? And if it is going to rain, do you have a tent? What if a passer-by pulls a cable that is being fused and is sticking out of the tent, will the jointer fall?

The fusion splicer also periodically needs to be serviced at different "levels": the minimum is to do the cleaning of electrodes with powerful current, to do arc calibration and calibrate the current strength in the arc. All this is programmed through the menu, and everything is described in the instructions. This is the case with Jilong KL-280; with Japanese fusion splicers, it is slightly different – there are separate self-testing programs. It is advisable to run these tests every time before starting work if the temperature / humidity of the air has changed after the previous calibration (it affects the arc), or many splices have been made since the previous calibration (the electrode ends have a bit of wear).

Sometimes you need to replace the electrodes (after several thousand splices) and the battery. Sometimes dust removal is required (by the way, it is forbidden to blow through with the balloon with compressed air – the mechanics is too sensitive). Sometimes something breaks down, gets misaligned, and full-service maintenance is required in the service center. In some Chinese products after 9999 splices (a very impressive number), the device is blocked, demanding to take it to a service center for full service.

As for the electrodes, there, of course, exist recommended splicing numbers indicated by the device manufacturer, after which it is advisable to replace electrodes. However, as the case may be, many operators fuse until they can go no further, which means until they obtain poor or failed splices and unstable arc.

After replacing electrodes, you must do the corresponding calibration by all means.