Top Answers on Ultrasonic Cleaning

20 most popular questions about ultrasonic cleaning and answers to all of them.

1. What is ultrasonic cleaning?

Ultrasonic cleaning is a fast and effective eco-safe cleaning method that uses ultrasound energy that penetrates a suitable cleaning solution. It provides high-speed thorough removal of unwanted soils from the items cleaned, that are situated inside the liquid container undergoing ultrasonic waves penetration. This cleaning method is one of the most up-to-date and efficient ways of dirt removal from different kind of objects particularly at no time and without possible item damage. The ultrasonic cleaning method is based on a cavitation effect.

2. What is cavitation?

Cavitation is the process of fast formation and dissipation of micro bubbles in a liquid. Cavitation effect takes place when the ultrasonic waves are passing through the liquid. Ultrasonic sound or ultrasound (high frequency sound, usually from 20 to 400 kHz) generates the alternating high and low pressure waves that produce tiny cavities (bubbles). They start growing from microscopic size at the low pressure phase until they are compressed and then implode during the high pressure phase. The molecules of a liquid collide releasing a huge amount of impact energy. The energy instantly increases the local temperature producing a high-energy stream that is aimed at the surface of the object being cleaned. These bubbles have enormous energy that is targeted at cleaning - its release lifts contamination off the surface cleaned.

3. How to get the ultrasound?

The ultrasonic energy of high frequency sound waves is converted from high frequency electrical energy by a transducer. The cleaning power of a unit depends on the type and power of the transducer used.

4. How is the ultrasonic cleaner designed?

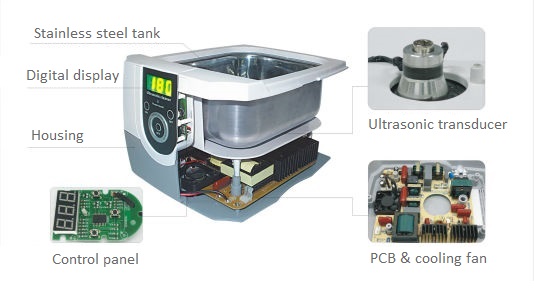

An ultrasonic cleaner unit design includes an ultrasound generator and special transducers that are installed on the bottom of a stainless steel tank. The tank is to be filled with liquid to form the cleaning environment. The generator together with the transducer form alternating waves of compression and expansion in the liquid at extremely high ratios, usually between 25 and 130 kHz.

5. What is the ultrasonic cleaner heater used for?

Ultrasonic cleaner uses heating function to keep the solution temperature at the needed level between the cleaning cycles. And the heat needed for cleaning is generated during the cavitation process.

6. What is degassing and what is it needed for?

Degassing is a process of preliminary removing the gases that may be present in the cleaning liquid. The cavitation is to occur only after gasses have been removed from the cleaning solution. That ensures vacuum in the bubbles formed. They collapse when the high pressure wave hits the bubble wall and the energy released assists a detergent in breaking the bonds between the objects cleaned and their soils.

7. How do I get the best cleaning result?

You may get the best possible ultrasonic cleaning result just following the simple steps: choose the proper type of the ultrasonic cleaner and the right size of the tank; choose the proper cleaning solution suitable for your purpose; set the correct temperature and amount of cleaning time.

8. What is direct cleaning and indirect cleaning?

When you place the items to be cleaned into an ultrasonic cleaner tank filled with cleaning solution – it is called direct cleaning. The objects are usually placed inside a special perforated plastic tray or basket, and not on the bottom of the cleaner tank. However, you must choose a solution that will not damage the ultrasonic cleaner tank for direct cleaning. Otherwise, you may use an inner non-perforated tray or a glass container, fill it with the cleaning liquid you need and place the items inside. This method is called indirect cleaning. Mind that the water level inside the tank itself should reach the fill line during the cleaning, i.e. about 1 inch from the top.

9. Why do we need a special solution for cleaning?

You may use different liquids for cleaning, even clean tap water. However, water itself has no cleaning properties, so you have to use a special cleaning solution to get the needed effect. You place the objects to be cleaned in it to start the process and the cavitation helps the solution to break the bonds between the items and the soils. Special ultrasonic cleaning solutions contain certain ingredients for enhancing the ultrasonic cleaning process. For instance, reduced fluid surface tension leads to increased cavitation levels. The liquid contains a good wetting agent or surfactant.

10. What cleaning solution should I use?

You may find a wide choice of ultrasonic cleaning solutions designed for specific applications. Modern solutions contain different detergents, wetting agents and other reactive components. A proper cleaning solution selection determines the successful cleaning process and helps avoid unwanted reactivity with the object being cleaned. Please, consult the technical experts before choosing the solution for your needs.

11. What cleaning solution shouldn't I use?

Never use flammable solutions or low-flash liquids (gasoline, benzene, acetone, etc.). Cavitation-induced energy generates heat and high temperatures may form dangerous environment in flammables. Avoid using bleaches and acids. They may damage the stainless steel tank of your cleaner. Otherwise, use them carefully if needed, however, for indirect cleaning only. The appropriate indirect cleaning container has to be provided, glass containers may be used.

12. When should I change the cleaning solution?

You are recommended to change cleaning solutions when the solution is visibly dirty or when the cleaning effect decreases. You don’t have to change the solution before every new cleaning operation.

13. Why must I keep solution at the tank's level indicator?

Make sure you keep the solution level at the cleaner level indicator every time before cleaning. It should correspond to the level indicator with trays and baskets inside. Otherwise, the cleaning process characteristics may be affected, the cleaner frequency might change, the cleaning effectiveness may be decreased and you may even get your cleaner damaged. Following this precaution helps provide the best solution circulation around the objects cleaned, and protects the device heaters and transducers from overheating and stress.

14. What is the cleaning process duration?

The cleaning time depends on several conditions, the most important of them are: cleaning solution, the amount and type of the soils on the object, cleaning temperature and the required cleanliness. You may witness the removal of soils right after the cleaning cycle starts. You may adjust the cleaning process duration according to your conditions. Usually, you set the approximately needed time, then check the cleaning result, and repeat the cleaning cycle if needed. Actual use and cleaning result help the operator determine the optimal cleaning time for certain types of the objects and for certain soils.

15. What is the recommended cleaning temperature?

Heating helps the cleaner make the cleaning process faster and more effective. Usually the cleaning solutions are created to provide best results and increased temperatures. You may determine the best temperature suitable for your needs to provide the most fast and effective results by conducting experiments with different types of soils and items cleaned. Usually, you may get the best results within the 50°C ~ 65°C range.

16. Should I rinse the items after cleaning?

In order to remove any harmful or unwanted chemical residue from cleaning solutions it is recommended to rinse the objects after cleaning. You may conduct rinsing in you ultrasonic cleaner filled with plain tap water, or use tap, distilled or deionized water and a separate container if needed.

17. Why should I switch the cleaner off when not in use?

Running the cleaner continuously on enhances the cleaning solution evaporation. This may lead to the low levels of the liquid in the tank that may finally cause serious damage to your cleaner. Switch the unit off after you finish the cleaning cycle and check the solution level before each operation in order to ensure long unit operation life.

18. Can ultrasonic cleaning damage my items?

This cleaning method, with some cautions, is considered safe for most objects. Though the during the cavitation process a powerful energy release occurs, it is safe as the energy is localized at the microscopic level. The first thing you should pay attention to is the correct choice of a cleaning solution. Ultrasonic power may enhance the effects of the detergent on the items cleaned. It is not recommended to apply ultrasonic method for cleaning the following gemstones: emerald, malachite, pearl, tanzanite, turquoise, opal, coral and lapis.

19. What are ultrasonic cleaning applications?

Typically this cleaning method is used for cleaning items, parts and other objects with complicated surface structure and items you should handle with extra care. Ultrasonic cleaning is helpful in chemistry, car industry, machinery, polymer products manufacturing, research, health care, medicine, gunnery, jewelry, industry.

20. What should I never do with the cleaner?

Never place the items on the bottom of the cleaner tank! This may cause the cleaner damage as the ultrasonic power will be reflected from the items cleaned back on the transducers. Always use a cleaning tray or basket, provide 30 mm distance between the tank bottom and the objects cleaned.

Never drop the cleaner and avoid other shocks. This may cause the ultrasonic emitter damage.

Never turn on the cleaner without the liquid inside the tank.

Never use flammables such as gasoline, benzene, acetone for the reasons of fire hazard.

Never operate your cleaner in extremely dusty areas.

Never operate your cleaner at extremely high temperatures for extended periods of time.

Never try to clean explosive items, ammunition, hand grenades, land mines, etc.

Never put animals or other live creatures inside the cleaner and don’t use the cleaner for cleaning your pets.

ToolBoom Online Store

Ultrasonic Cleaners: Popular Models

One of the brands producing ultrasonic cleaners, that have proven their reliability, is Jeken, previously known as Codyson. They are manufactured on the Chinese enterprise Jeken Ultrasonic Cleaner Limited according to Japanese and German technologies since 1998.

People often buy the following cleaners with plastic housings to be used as ultrasonic jewelry cleaners in jewelry stores and workshops, for household applications and more:

The manufacturer have produced a series of cleaners in metal housings used for the above mentioned applications, as well as in workshops, medical institutions, antiquarian shops, electronics repair centers, manufacturing enterprises.

This is the list of basic applications and recommended models, to get more information and help in choosing the required ultrasonic cleaner, fell free to contact our tech support.