Tools and Equipment for Setting up a Service Center

In this article, we will try to help you establish a workshop for servicing electronics from the very beginning. We've systematized the information as much as possible so that you can easily find the equipment essential for mobile phones, tablets, laptops, game consoles, and other gadgets and devices repair.

So, where do we begin? First, we need to make a list of equipment categories.

To have a fully functional service center we need:

Soldering equipment

Probably the most important component of any service center is its soldering basis. Thus, you can't only have a soldering iron that is used to repair mobile phones. For full-fledged works and in order to feel confident in all repair situations, the service center should have several types of soldering stations and systems.

For instance, repairing laptops and motherboards will be mainly carried out using a semi-automatic BGA rework systems.

We may note two models out of the whole range of such equipment, namely ACHI IR-PRO-SC and ACHI IR-6500. These rework systems are perfect for BGA soldering on large area PCBs. Large bottom preheaters minimize the risk of textolite thermal deformation, and multi-zone temperature monitoring prevents chip overheating when the thermal profile is chosen correctly.

QUICK 7710 lead-free BGA rework system is reliable semi-automatic equipment that allows the dismantling of faulty chips and mounting new ones quickly. The large bottom preheater and the precision working table ensure the meticulous repair of complex electronic devices.

Obviously, the repair works are not restricted to BGA only. That is why the working place should also be equipped with a soldering iron, as well as with a heat gun.

Nowadays, most manufacturers offer combined solutions in this market segment. Usually, hot air soldering stations are equipped with contact soldering irons and hot air guns. Such a design helps to save the working space, which is quite important. Manufacturers produce a huge number of models. Mostly these stations differ only in the soldering iron power (35 W, 50 W, 70 W – the most typical power values) and the hot air gun type (turbine or compressor).

Regarding soldering irons, it's obvious that a compact, powerful tool is more practical and versatile than a low-powered one. As for the hot air guns, both turbine and compressor ones have both advantages and disadvantages. Let's not enlarge on this, as you can easily find all the pros and cons of these tools online. It's up to an engineer which design is more suitable for them.

Mass market inexpensive soldering stations by Lukey, BAKU, AOYUE, YIHUA provide decent quality for little money. There are no significant differences between these stations, so feel free to purchase any model you like.

Recently, the high-quality soldering stations made by Ukrainian brand Accta have become popular in the soldering equipment market. These are hot air rework stations equipped with a hot air gun and a soldering iron. There're three main models of these stations: Accta 301 (the soldering iron is compatible with all Hakko 900M type soldering tips), Accta 401 (the soldering iron is compatible with Hakko T12 type soldering tips), Accta 501 (the soldering iron is compatible with Japanese Goot 80HRT series soldering tips).

These stations feature compact size, real-time temperature indication, and a multi-level protection system that ensures safe and reliable equipment operation.

In addition to standard tools, such as soldering irons and hot air guns, some stations are equipped with other useful add-ons: a desoldering gun, a smoke absorber, hot tweezers for mounting/demounting of electronic components, and vacuum pick-up tweezers for quick microcircuit dismantling. There are many soldering stations with extended functionality, but we recommend you to look to the following ones: Goot TP-100AS, QUICK 702 ESD, QUICK 713 ESD.

You may find information concerning what you need for BGA reballing in one of our previous articles. However, soldering equipment is not the only equipment you need for a repair workshop.

Measuring equipment

For troubleshooting cellphones, tablets, laptops and conducting measurements during the repair process you need measuring equipment.

A set of measuring equipment in a service center should include the following:

- multimeter

- oscilloscope

- battery analyzer

A mid-range multimeter is the best option for a service center. Keep in mind that an inexpensive device won't let you perform all the operations that may arise while maintaining complex electronics. Besides the basic features, your multimeter should be highly precise, and have functions of measuring capacitance, and temperature.

We assure multimeters made by UNI-T and OWON are quite a good choice. These brands offer reliable and reasonably accurate models in the mid-range price range. Also, their functions are enough to perform all types of repairing.

However, we recommend you to have an additional inexpensive compact multimeter on hand to carry out simple measurements such as continuity, voltage, or resistance. These tools are a good choice you're not going to regret: Accta AT-205, UNI-T UT39A+, UNI-T UT33C+.

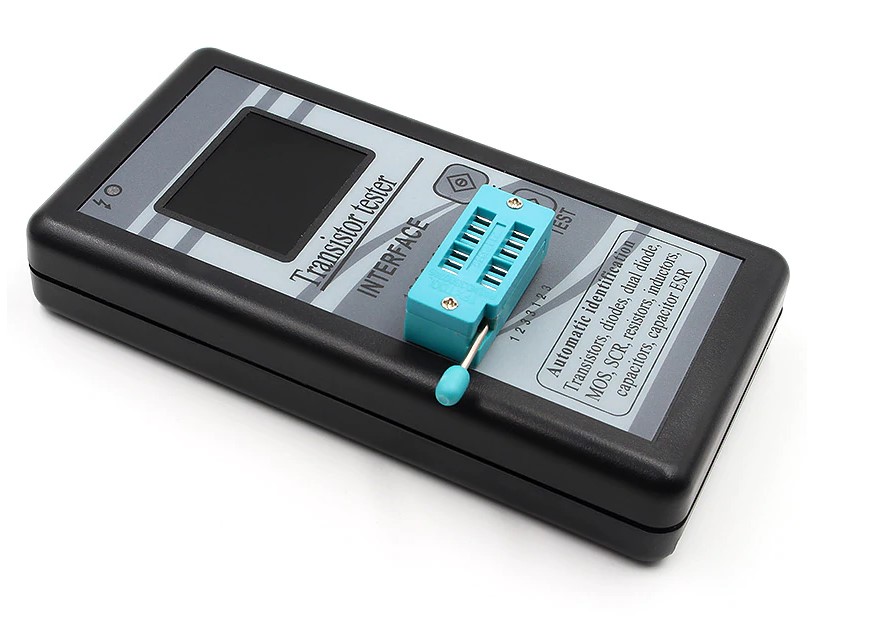

Besides, you'll need a simple and inexpensive electronic component tester by FNIRSI for testing transistors, diodes, capacitors, and inductors. Also, be sure to get the unique BOKAR Smart Tweezers ST-5-S for SMD components checking.

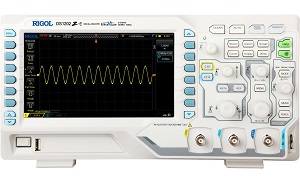

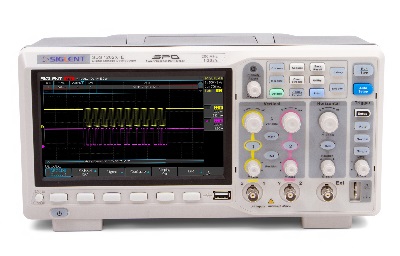

Huge changes have taken place in the budget oscilloscope market over the last few years. These days, mid-range devices have features that were previously only available in expensive models. The typical bandwidth of a modern budget oscilloscope is 100-200 MHz and a memory depth of 12-14 million points.

Many budget models have the function of decoding digital protocols, and you can expand their functionality by purchasing additional software licenses. Moreover, these software licenses may be pre-activated in oscilloscopes (for a limited period and at no cost). This helps you to decide if you really need it and then make a decision on the purchase.

One of the leaders in the class of low-price oscilloscopes is SIGLENT SDS1202X-E. This tool's specifications equate to the ones of higher-end oscilloscopes. The SIGLENT SDS1000X-E series was originally supposed to be a line of low-cost devices with wide functionality. However, the first model has become so popular that more advanced oscilloscopes with four channels and a logic analyzer function appeared. (SIGLENT SDS1204X-E, software option).

The reason for portable device failures often lies in the power source. There are many interesting and inexpensive solutions available today for checking batteries.

If you need to measure the internal resistance of batteries and battery assemblies, you need to have a high-precision battery tester like YR1035C5. With this device, you can quickly test a lot of batteries of any type, from automobiles to ordinary 18650 cells, with voltages up to 100 V.

The FNIRSI series of USB testers are compact and affordable devices that allow to quickly and accurate check the battery of almost any device (smartphone, tablet, player), and also test the performance of chargers, U-disks, data cables, power supplies, etc.

Hand tools

The huge variety of screws used in the devices by different manufacturers requires proper amount of tools for screwing/unscrewing them. The most reasonable solution to this issue is buying a screwdriver with a set of bits.

You may find almost every bit that is used nowadays in Pro'sKit SD-9808N kit screwdriver set. However, for disassembling modern cell phones and Apple products you will need specialized sets, such as Pro'sKit SD-9314 and Pro'sKit SD-9322M.

You should choose several types of tweezers for different components:

- Pro'sKit 1PK-101T is good for SMD

- Pro'sKit TZ-100C or Pro'sKit TZ-100A for digital elements

- Pro'sKit TZ-300A anti-static tweezers are necessary for sensitive components

You will also require cutting pliers of the following types:

- micro cutting pliers for small components: Pro'sKit PA-101

- middle-size pliers for most applications: Pro'sKit 8PK-905

- large cutting pliers for wire cutting: Pro'sKit 1PK-067DS

You will also need soldering aid tools:

- a set of probes for BGA elementsPro'sKit 1PK-3178

- a set of soldering tools GOOT SA-10

Power supply units

Among the great variety of power supply units, you should choose the most multi-purpose model with the parameters exceeding the required ones by 30-40%. This may significantly increase the PSU lifetime and ensures its operation without failure.

The most popular models are:

For simple applications, you can use a programmable single channel DC step-down power supply buck converter such as the FNIRSI DC-6006L. Despite its small dimensions and low price, this tool is no worse than more expensive devices.

Optical equipment

And finally, we will try to get our eyes ready. It is not a secret that you can not do without a microscope while repairing modern PCBs, some SMD components may be only up to 1 mm long. Repair microscopes were created for soldering and checking such components. They differ from, say, biological microscopes because they have a larger distance between the objective and the observed surface. It may equal up to 15-17 cm. This parameter is very important, as the larger is the distance, the more convenient it is to use soldering iron/fan/other tools under the microscope. Usually, they are equipped with a rotation objective with the regulated zoom factor that equals 10~20~40x. Upper illumination is a must.

We should mention the most popular models:

- ST60-24B2 Binocular Microscope

- ST-series SZM45-B2 Binocular Microscope

- ST-series ST-B-P Binocular Microscope

However, despite optical microscopes' reliability, they're gradually being replaced by modern electronic devices. Broadly speaking, USB-microscopes may be classified under two groups: devices without a display (the image is displayed on a computer screen) and microscopes with a built-in display.

For the tasks requiring less magnification than the microscope may provide, it is reasonable to use a desktop magnifying lamp. It may be also used as a light source. For repair works, we recommend lamps with no more than 3 diopters magnification, like the Bourya 8066HLED.

That was our short review of the most needed equipment for setting up a service center. No doubt that we managed to mention not all the required equipment, but the complete list depends on the service peculiarities. You may contact our technical support experts for more detailed information.